Research Project Title: Bond Performance of Structural Concrete from Recycled Coarse and Fine Aggregates

Research Abstract:

The need for concrete to drive the infrastructure needs from society cannot be over emphasized. Hitherto, the construction industry will continue to extract natural resources for concrete production while efforts to replenish these resources are almost non-existent. Focusing on sustainable use of recycled coarse and fine aggregates would contribute to nearly 80% by mass of the concrete volumes being used for construction. Current standards are limiting the use of recycled aggregates for non-structural and structural applications and it is important to establish especially what structural detailing provisions need to be in place when 100% recycled concrete is allowed. Erring on the side of safety has always been the norm in engineering practice and would continue to be a guiding principle in this research

Project Team:

[1] Shahria M. Alam

[2] Charles Rockson

[3] Humera Ahmed

Publications:

Ongoing

Collaborators:

Research Project Title: Green concrete with recycled aggregates

Research Abstract:

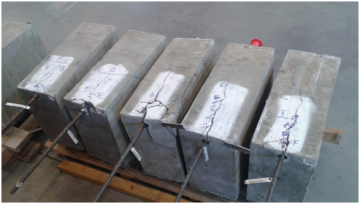

Kishoare’s research primarily focuses on the effective utilization of recycled waste materials in concrete to reduce environmental loads and thereby, promote sustainable green concrete production. She has integrated recycled crumb rubber (CR) and recycled concrete aggregates (RCA) as partial replacements of natural fine aggregates (NFA) and natural coarse aggregates (NCA), respectively, in concrete to study their effects on the mechanical properties of the new concrete. Moreover, she is also investigating the efficacy of using synthetic fibers in addition to CR and RCA to enhance the flexural strength of the green concrete. Use of such recycled materials in concrete can contribute substantially towards the production of green concrete, and can provide a viable solution to address the harmful environmental effects of concrete production and solid waste disposal.

Project Team:

[1] Shahria M. Alam

[2] Kishoare Tamanna

Publications:

- Tamanna. K, Pour S.M., Banthia. N, and Alam, M.S. (2017). Experimental investigation of mechanical properties of rubberized concrete containing recycled coarse aggregate. 6th Int Conference on Engineering Mechanics and Materials, CSCE, Vancouver, BC, May–June 2017, Paper ID: 520

- Tamanna. K, Banthia. N, Alam M.S. (2018). A Review of the investigation of impact re-sistance of rubberized concrete containing. 1st International Conference on New Horizons in Green Civil Engineering (NHICE-01), Victoria, BC, Canada, April 25 – 27, 2018, BC, Paper ID: 057

- Tamanna. K, Banthia. N, Alam M.S. (2019). Experimental Investigation on the Flexural Behavior of Rubberized Concrete Containing Recycled Concrete Aggregate and Poly-propylene Fiber. Abstract submitted to 7th International Specialty Conference on Engineering Mechanics and Materials, CSCE, June 12 – 15, 2019, Laval, QC, Paper ID: 3

Collaborators:

Research Project Title: High performance recycled aggregate concrete

Research Abstract:

Humera’s research interests are sustainable construction materials and advanced cementitious materials. Humera’s thesis work revolves around development of high performance recycled aggregate concrete using different enhancement techniques, which must be sustainable themselves. Globally, the construction industry is the largest contributor to the carbon footprint and a major consumer of natural resources. In addition to this, waste generated by this industry is non-biodegradable and consumes valuable public space in the form of landfills. According to an estimate, the amount of construction and demolition (C&D) waste generated annually by North America is around 175 million tons and Canada alone produces 9 million tons per year. Also, the rate of recycling C&D waste in Canada is very low, approximately 27 % of this waste is fed to landfills. In addition to this, Canadian standard association only allows the use of RCA up to 30% which is very low as compared to other standards. Humera’s work will contribute as the guidelines to produce high performance concrete, as well as the basis for updating current Canadian standards.

Project Team:

[1] Shahria M. Alam

[2] Humera Ahmed

Publications:

Ongoing

Collaborators:

Research Project Title: Seismic evaluation of bridge piers built using recycled concrete aggregates

Research Abstract:

Maher’s research primarily focuses on the effective utilization of recycled waste materials in concrete to reduce environmental loads and thereby, promote sustainable green concrete production. He has integrated recycled concrete aggregates (RCA) as a replacements of natural coarse aggregates (NCA), in reinforced concrete bridge piers to study their effects on the seismic performance of the structure using the new concrete. Moreover, He is also investigating the feasibility of using RCA in high seismic regions as part the green concrete. Use of such recycled materials in concrete can contribute substantially towards the production of green concrete and can provide a viable solution to address the harmful environmental effects of concrete production and solid waste disposal.

Project Team:

[1] M. Shahria Alam

[2] Maher AL-Hawarneh

Publications:

Ongoing